Dyed woven fabric has transformed the textile industry. It combines artistry with technology to create vibrant textiles. Renowned fabric expert, Dr. Emily Hart, notes, “Dyed woven fabric elevates any design with its rich colors and textures.”

To make this fabric, yarns are dyed before weaving. This process allows colors to penetrate deeply. Various methods include yarn dyeing and piece dyeing. Each method offers unique aesthetics and functionality. However, achieving consistent color can be a challenge.

This craft demands attention to detail and skill. Imperfections in dye absorption may lead to unexpected results. These moments often spark innovation. They drive designers to experiment and rethink their approaches. Dyed woven fabric not only tells a story but also reflects the complexities of its creation.

Dyed woven fabric is a textile created through the intricate process of weaving dyed threads. This fabric is notable for its vibrant colors and unique patterns. The dyeing process can occur before or after the weaving. Each method has its benefits. Pre-dyed threads can ensure consistent color throughout the fabric. However, post-dyeing allows for more creative designs and patterns.

The characteristics of dyed woven fabric are diverse. It often boasts durability and a certain crispness. The tight weaving technique contributes to its strength. Yet, this fabric can sometimes fade with exposure to sunlight or harsh washing. The colors may lose their brilliance over time, presenting a challenge for maintaining its aesthetic appeal. Additionally, variations in dye absorption can lead to unexpected results, sometimes creating unintended patterns.

Working with dyed woven fabric can be rewarding yet challenging. The process requires skill and experience. Color mismatches can occur, impacting the final product. Understanding how dyes interact with different fibers is crucial. At times, results may not align with the initial vision. This discrepancy often leads to reflection and adjustment in future projects. Overall, dyed woven fabric presents both beauty and complexity in its creation.

Dyeing woven fabric is a fascinating process. Many techniques exist, each with unique outcomes. The choice of method impacts color intensity and durability. The global textile dyeing industry is projected to reach $23 billion by 2027. This expansion highlights the importance of efficient and sustainable dyeing practices.

One of the most common techniques is reactive dyeing. Reactive dyes bond chemically to the fabric. This results in vibrant colors and good wash fastness. But it has drawbacks. The process requires specific conditions and can produce wastewater. According to the Environmental Protection Agency (EPA), dyeing operations can generate large amounts of polluted water.

Another method is acid dyeing, typically for protein fibers like silk or wool. This technique produces rich, deep hues. Yet, it also raises environmental concerns. The chemicals used can be hazardous. Striking a balance between vibrant results and sustainability is crucial. Reports show that more brands are seeking eco-friendly alternatives. The industry acknowledges the need for improvement and innovation.

| Dyeing Technique | Description | Common Uses | Environmental Impact |

|---|---|---|---|

| Bathtub Dyeing | Dyeing in small batches using a bathtub, often utilized for unique color combinations. | Artisanal fabrics, custom designs. | Minimal if using natural dyes; higher with synthetic options. |

| Machine Dyeing | Utilizes industrial dyeing machines for large volume production with consistent results. | Wide range of apparel, home textiles. | Varies; efforts are underway to reduce water and chemical use. |

| Tie-Dyeing | A manual method of dyeing fabric by tying sections to resist dye, creating unique patterns. | Casual apparel, festival wear. | Low impact with natural dyes; more environmental if using eco-friendly practices. |

| Screen Printing | A method where ink is pushed through a screen to create designs on fabric. | T-shirts, bags, and other promotional materials. | Can be harmful if non-eco inks are used; better with water-based inks. |

| Natural Dyeing | Utilizes dyes derived from plants, minerals, and insects. | Eco-friendly textiles, artisanal products. | Generally low environmental impact; sustainable practices are critical. |

Weaving is a fundamental textile technique that transforms yarn into fabric. There are various types of woven fabrics, each with its own unique characteristics. For instance, plain weave is the simplest form. It involves weaving warp and weft threads over and under each other. This method is easy to produce and creates a flat, sturdy cloth.

Another type is twill weave, which forms a diagonal pattern. This results in a textured surface. Twill fabrics are often more durable and drape beautifully. They are commonly used in jeans and jackets. Satin weave, on the other hand, creates a shiny surface with a smooth finish. It uses fewer interlacing points, allowing threads to float over each other.

Woven fabrics can have different functions. Some are designed for everyday wear, while others serve more specialized needs. The process of weaving may seem straightforward, but it requires precision and skill. Mistakes can lead to flaws in the fabric. Understanding these weaving types enhances appreciation for the craftsmanship involved. Each fabric tells a story of creativity and innovation through its construction.

Quality control in dyed woven fabric production is essential for maintaining high standards. It starts with the selection of raw materials. Quality fibers are crucial. Poor quality materials can lead to uneven dyeing and defects. Each batch of yarn should be tested for consistency before weaving begins.

During the dyeing process, samples should be taken regularly. This ensures the colors are vibrant and match the required specifications. Monitoring the dyeing temperature and time is vital. Deviations from these parameters can result in color discrepancies. It is important to maintain meticulous records of each dye lot. This helps in tracing back any issues that arise later.

Tip: Always conduct pre-production dye tests. This can reveal potential problems early on.

After weaving, the finished fabric should undergo inspection. Look for uneven color patches or defects. A final quality check helps catch flaws before the fabric is sent out. It’s crucial to encourage a culture of quality awareness among workers. Everyone should take responsibility for maintaining standards.

Tip: Train staff regularly on quality control measures. This keeps everyone aligned on goals.

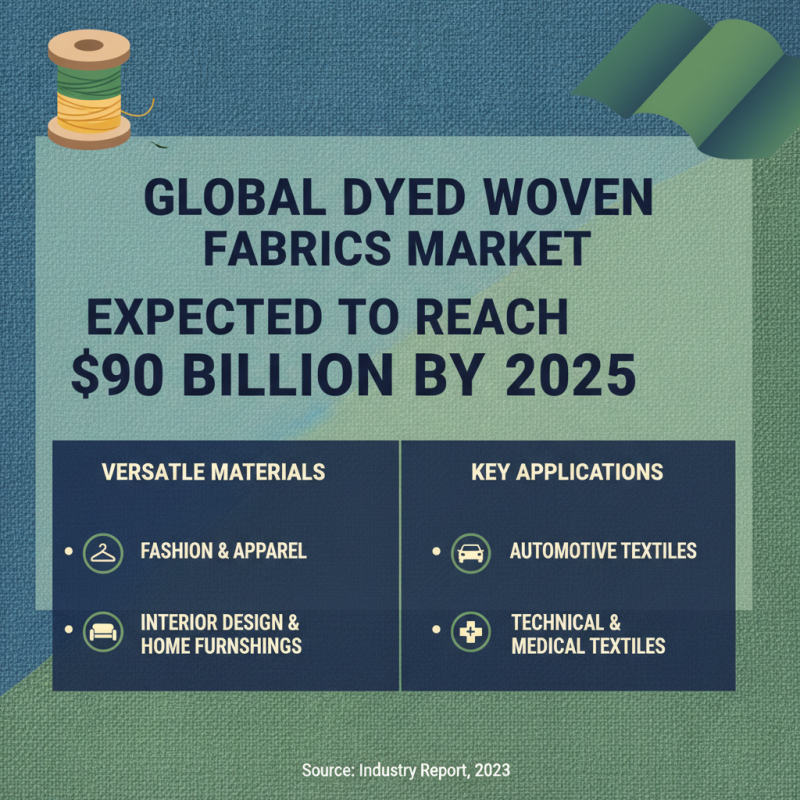

Dyed woven fabrics are versatile materials used across various industries. These fabrics are often found in fashion and interior design, where color and texture make a significant impact. According to a recent report, the global dyed fabric market is expected to reach $90 billion by 2025, highlighting their growing importance.

In the automotive industry, dyed woven fabrics are utilized for seating and interior trims. They are preferred for their durability and aesthetic appeal. Surveys indicate that 70% of consumers consider fabric color when purchasing vehicles. This trend underscores the need for manufacturers to focus on high-quality dyed fabrics.

Tips: When selecting dyed woven fabrics, consider the intended use. Not all dyes are suitable for every application, as some may fade or wear quickly. Also, recommend testing a small sample before committing to large orders.

In the furniture sector, these fabrics enhance visual appeal. However, the sustainability of dyeing processes is often overlooked. Proper eco-friendly options exist, but not all manufacturers prioritize them. Reflecting on this can lead to better choices in material sourcing.