Choosing the right Elastic Stretch Fabric for your projects can significantly impact the final results. The growing demand for stretch fabrics has been noted in industry reports. The global market for elastic fabrics is projected to reach $15 billion by 2025. This highlights their rising importance in various applications, from fashion to sportswear.

When selecting Elastic Stretch Fabric, consider the fabric's composition and stretchability. Various blends offer different levels of durability and comfort. Fabrics like spandex are known for their exceptional elasticity. However, some consumers are concerned about the environmental impact of synthetic materials. This is an area that requires careful reflection as we move forward.

Understanding your project's requirements is crucial. Not all stretch fabrics perform similarly under different conditions. Some may lose their elasticity over time, which can affect wearability. Thus, testing and reviewing options may lead to a better choice. In the end, choosing Elastic Stretch Fabric requires thoughtful consideration of both performance and sustainability.

Choosing the right elastic stretch fabric involves understanding its types and properties. There are several main types to consider: spandex, lycra, and elastane. These materials provide excellent stretch and recover quickly. A report from the Textile World notes that fabrics containing at least 10% of these elastomers offer optimal elasticity for activewear.

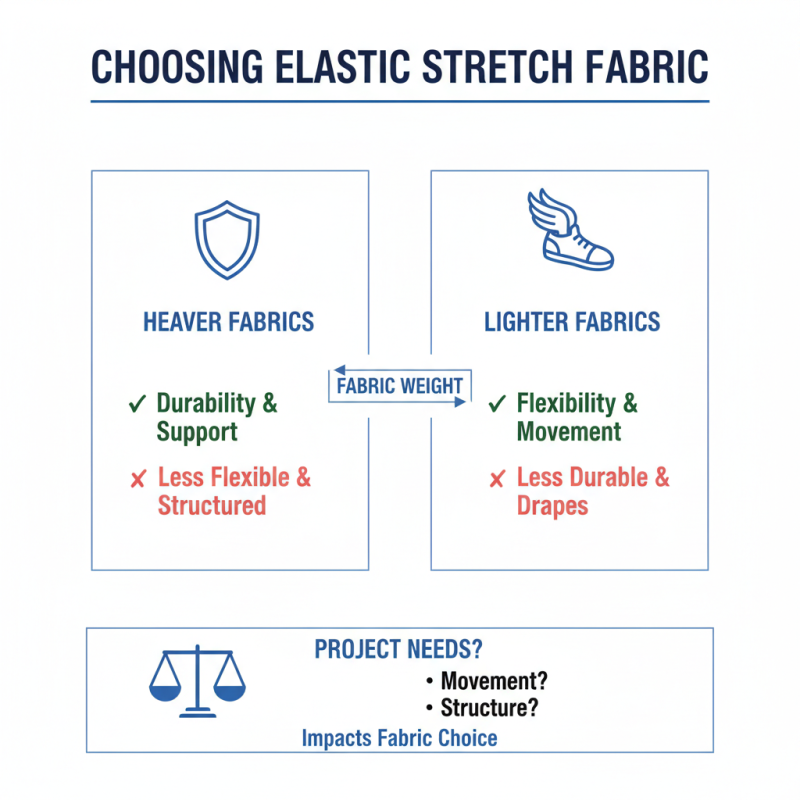

When selecting fabric, it's essential to assess its weight and thickness. Lightweight materials are great for layering. Heavier fabrics may be more suitable for structured garments. According to a study by the ASTM, heavier fabrics can offer better durability but may sacrifice breathability.

Identifying the right stretch type is equally important. Four-way stretch offers flexibility in multiple directions, while two-way stretch is limited. You may find that some fabrics don’t meet your expectations. They might lack the promised elasticity or feel uncomfortable against the skin. This unfulfilled promise can lead to dissatisfaction in your projects. Therefore, testing a sample before making a bulk purchase is essential.

Choosing the right elastic stretch fabric can be daunting. There are several factors to keep in mind. Look for the right weight and thickness. A heavier fabric may not be suitable for delicate projects. Conversely, lightweight fabrics might not provide enough support for structured garments.

Consider the stretch capability. Some fabrics stretch in one direction, while others stretch in both. It is essential to match the fabric’s stretch with your project requirements. Additionally, think about the fabric’s recovery. A fabric that doesn’t bounce back can lead to sagging, which isn’t ideal for fitted designs.

Don’t overlook the texture and finish of the fabric. Soft textures work better for close-fitting items, while sturdier finishes can create a lasting structure. Lastly, remember to test different fabric samples. Not all fabrics behave the same, and sometimes your initial choice may not perform as expected. Understanding these nuances can significantly impact your project outcomes.

When choosing elastic stretch fabric, evaluating fabric weight is crucial. Heavier fabrics offer durability but may lack flexibility. Lighter fabrics provide excellent stretch but might not hold up over time. Consider how the fabric will perform in your project. Does it need to support movement or remain structured? This decision impacts the fabric choice significantly.

Stretchability is another key factor. Some fabrics stretch in one direction, while others offer four-way stretch. For athletic wear, four-way stretch is ideal. It allows for full range of motion. For structured garments, a two-way stretch might suffice. Testing the fabric before making a purchase is beneficial.

Tips: Always stretch the fabric in-store. Feel how it responds. Also, check the recovery. How quickly does the fabric return to shape? A poor recovery can lead to sagging over time. Lastly, remember that different projects may require different fabric weights. A miscalculation here can lead to disappointing results. Choose thoughtfully!

Elastic stretch fabric serves many industries, offering versatility and comfort. In fashion, this material shapes garments for a flattering fit. Activewear benefits from its durability and movement flexibility. Athletic clothing often includes this fabric, allowing for unrestricted motion during workouts.

In upholstery, elastic stretch fabric is commonly used. It helps create cozy, inviting spaces. Furniture covers crafted from this material adapt to various shapes. This flexibility ensures a snug fit, enhancing the aesthetic appeal of sofas and cushions.

Tips for selecting the right fabric: always test stretch ability. Pull the fabric and observe how it returns to shape. Consider weight, too. Lighter materials are better for summer clothes, while heavier options work for winter garments. Ensure you account for the fabric's recovery—how well it maintains its shape over time. Perfect choices can make all the difference in your projects.

| Application Area | Fabric Type | Stretch Ratio | Common Uses |

|---|---|---|---|

| Activewear | Polyester-Spandex Blend | 4-way Stretch | Yoga pants, sports bras, gym shorts |

| Fashion Apparel | Cotton-Spandex Blend | 2-way Stretch | Dresses, fitted tops, skirts |

| Medical & Healthcare | Nylon-Spandex Blend | 4-way Stretch | Compression garments, bandages |

| Automotive | Polyurethane Coated Fabric | 2-way Stretch | Seat covers, upholstery |

| Home Décor | Canvas Stretch Fabric | 1-way Stretch | Cushions, curtains |

When working with elastic stretch fabrics, care and maintenance are vital for longevity. Most elastics lose their ability to stretch after numerous washes. A recent study from the Textile Research Institute indicates that proper washing reduces fabric degradation by up to 30%. Use cold water and a gentle cycle to preserve the elasticity and color.

After washing, air drying is crucial. Heat can cause shrinkage and weaken the fibers. Reports suggest that fabrics dried at high temperatures lose up to 40% of their elastic quality. If you must use a dryer, opt for low heat. Remember that improper care may lead to unsightly lumps and loss of shape.

Regular inspection is equally important. Look for signs of wear, like fraying or fading. These issues can be subtle; even a small tear can compromise the garment. Ignoring minor damage may lead to larger problems later. Be proactive in repairing any defects to maintain the fabric in excellent condition.